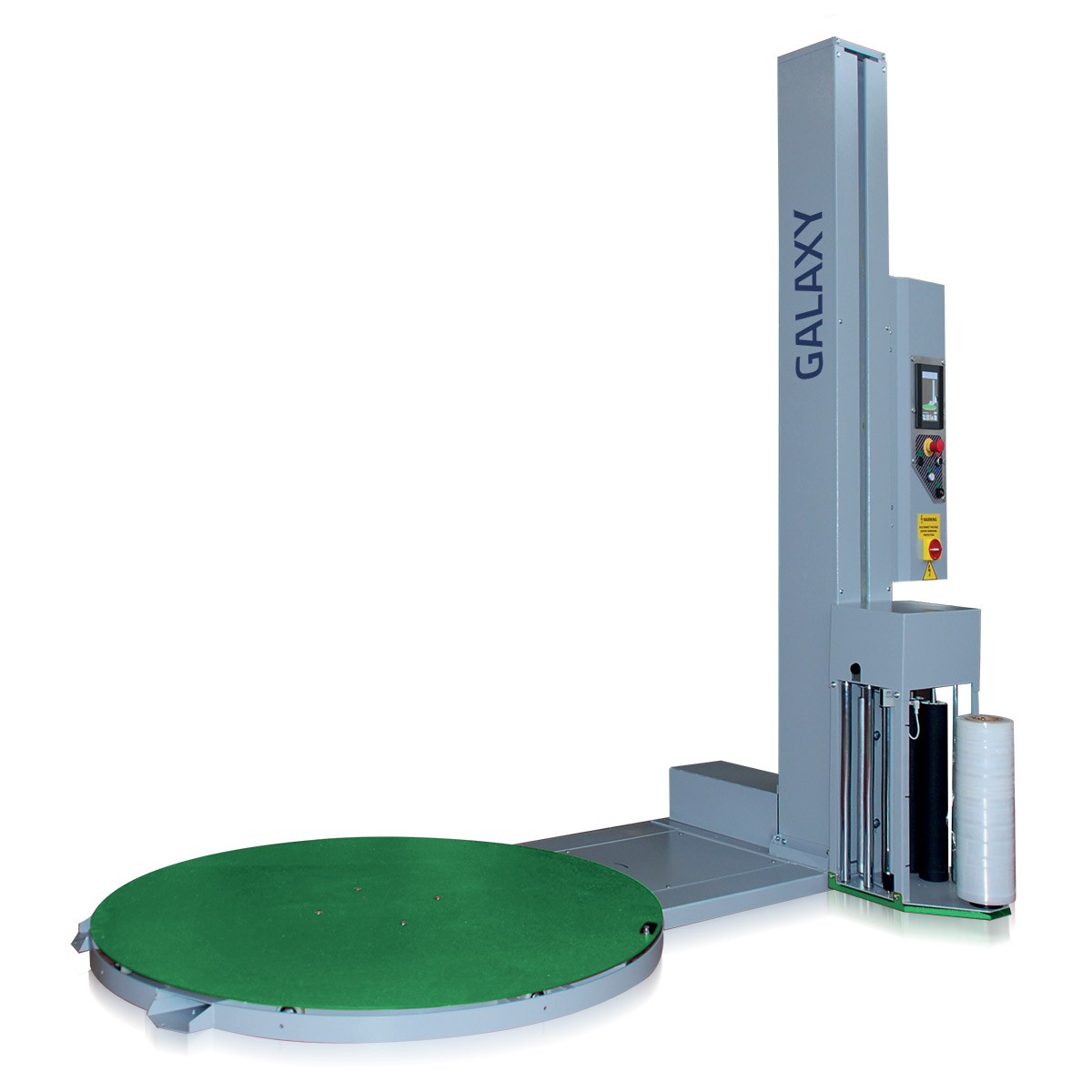

MACHINE FOR STRETCH FILM PALLET WRAPPING HORBITEK GALAXY

7700,00 €

1 in stock

HORBITEK

Semi-automatic turntable machine for stretch film pallet wrapping. High technology and reliability. Designed to solve any packaging requirement.

1 in stock

ALL PRICES ARE NET AND DO NOT INCLUDE 23% VAT

Description

HORBITEK GALAXY – MACHINE FOR STRETCH FILM PALLET WRAPPING

Semi-automatic turntable machine for stretch film pallet wrapping.

High technology and reliability.

Designed to solve any packaging requirement.

High quality machine for wrapping pallets with stretch film.

The structure of the machine is heavy type, built with thick steel sheets.

It’s good to all warehouses and is ideal for intense and heavy work.

Practical and robust.

The machine is built entirely of steel and is composed of a reinforced base on which derlin wheels are mounted. For this reason, the machine can also pack pallets weighing up to 2100 kg (opt up to 3000 kg). The transmission is a 5/8-inch chain to ensure more precise starts and stops, with less maintenance and longer life.

Solid lifting column.

The structure of the column is built with thick sheet metal (1.5 mm) to ensure perfect and long-lasting vertical movement of the reel-holder carriage. The transmission of the reel-holder carriage takes place via a closed-loop chain.

Complete control of the machine.

The rotation of the Pallet and the lifting of the reel-holder carriage are managed by inverters to be able to vary the speeds of all movements. In this way it is possible to optimize the wrapping in each phase of the packaging.

With the inverter it is also possible to obtain a gradual start of the plate to avoid overturning of unstable pallets. It is also possible to obtain an exact phase stop of the plate with tolerances of only 20mm.

The machine is easy to use.

The operator simply loads the pallet to be wrapped in the centre of the plate, hooks the edge of the film and press start. The machine will automatically wrap the pallet. A photocell will automatically detect the pallet height and at the end of the cycle the pallet will stop in phase position to be able to be unloaded with the forklift.

Length (min-max) mm 600 – 1200

Width (loading side) (min-max) mm 600 – 800

Minimum and maximum loading height (including pallet) mm 600 – 2000 (pallet 120 mm).

Minimum and maximum loading weight (min-max) kg 70 – 2000

Maximum load sag mm 20

Maximum protrusion of the load mm 20

Profile height above the transport mm 120

Rotary table diameter mm 1500

Power supply Kw 220V 1 Ph + N + Gr (1.1 Kw)

Color of solid elements Ral 7040, The color of the moving parts is Ral 6037

Rotation speed rpm 10.

Material 100% LLDPE

Thickness 10 – 27 Microns, Roll weight Max 20 kg, 500mm tape

Inner diameter 50-76mm, Roll outer diameter Max 300 mm

Prestretch (Optional – not included) 50 – 400%

Easy operation thanks to the intuitive display with a selection of programs such as:

Partial top and bottom packing only, full top and bottom packing, manual movement, pallet height setting excluding photocell, top protection wrapping, heavy duty wrapping with preset position, wrapping started at a preset height, parameter protection password setting and ability for storing 98 custom programs.

Adjustment of parameters such as:

Table rotation speed, trolley up/down speed, number of wraps from the bottom, number of wraps on top, number of reinforced wraps and height setting, packing start height, photocell delay for pallet protrusion and setting for the upper protective layer.

The machine is equipped with a safety device:

emergency button compliant with applicable CE standards. machine reset button in accordance with applicable CE standards. – emergency and safety button on the foil feeding system.

ADDITIONAL EQUIPMENT INCLUDED IN THE OFFER:

Powered “PM” Reel Carriage Fully powered pre-tensioning: the carriage is equipped with 2 vulcanized rollers to pre-stretch the film during unwinding. Standard tension ratio 230%, available from 50% to 350%. An electronic system together with movable rollers regulates the amount of film required for wrapping and a pallet packing mast with a height of 2400 mm.