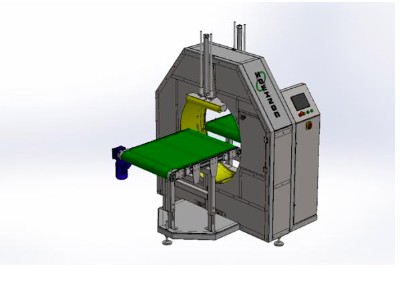

AUTOMATIC WRAPPING MACHINE HORBITEK HORIZON 1200-SX

23500,00 €

1 in stock

HORBITEK

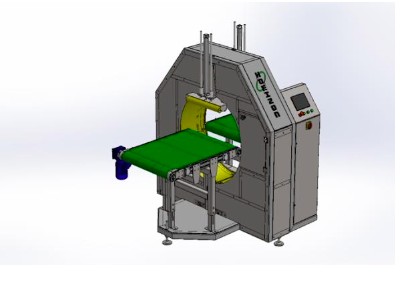

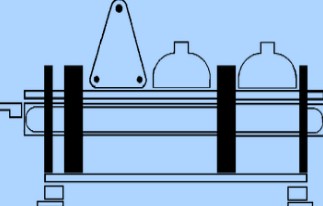

Automatic horizontal wrapper with rotating ring. The base is made of a solid welded steel tube in which the machine components are fixed.

1 in stock

ALL PRICES ARE NET AND DO NOT INCLUDE 23% VAT

Description

AUTOMATIC WRAPPING MACHINE MODEL HORIZON 1200-SX

Automatic horizontal wrapper with rotating ring. The base is made of a solid welded steel tube in which the machine components are fixed.

Technical data

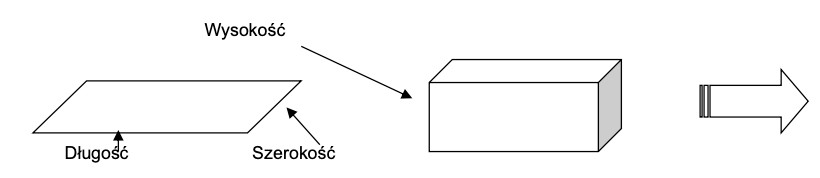

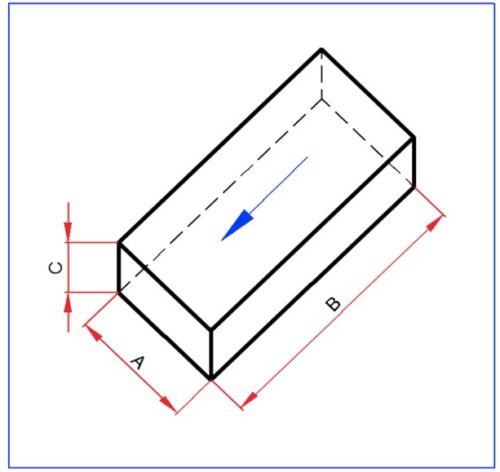

Wrapping width min. 80 max. 1000 mm, wrapping length min. 400 max. 3000 mm,

wrapping height min. 10 max. 500mm, weight max. 100 kg

Working level mm 1000

Conveyor speed m/min 8-10

Max capacity Packs/h (*) 100

Compressed air demand Bar (+/-1) 6; 30NI/min

Power supply 220V 1P + N + T (3 phases) 3 kW

The color of the permanent components is Ral 7040 The color of the moving components is Ral 6037

(*) – the value given is based on a stable load of 1000 mm and 20 wraps of film (therefore, the capacity is variable as a function of the length of the load and the wrapping cycle).

Material 100% LLDPE, Thickness 17- 30 Micron, Roll weight max 9 kg, Tape – width 125 mm, Internal diameter 76 mm, The outer diameter of the roll max 250 mm.

Semi-automatic wrapping machine with a horizontal axis and an encircling ring with an inner diameter of 1200 mm. Welded steel construction, Construction complete with access door to replace the roller with electromechanical micro protection. The ring is equipped with a high-quality steel wheel that can withstand up to 80 rpm.

The rotation is performed by a self-locking motor driven by an inverter. The film application trolley, supporting the film roll, provides adjustable tension depending on production needs. Input/output pinch rollers provide increased rigidity to the load during the wrapping cycle.

Each group consists of two PVC-coated idle rollers attached to the support. Activation of the unit by means of a pneumatic actuator, the possibility of adjusting the pressure by means of a manometer.

Electrical panel built into the machine, control by PLC.

Conveyors Loading conveyor belt L 1200 x 1000 mm controlled by an inverter.

Unloading conveyor belt L 1200 x 1000 mm controlled by an inverter.

Strengths and benefits of the machine

Balanced and safe ring (no welds) Single electrical control panel with PLC and touch panel color operator interface that allows you to adjust various multi-program cycles Electrical panel built into the structure of the machine and lifted off the ground (there are no cables on the ground) and there are no obstacles next to the machine) Avoid nuisance film breaks

Durability and robustness in relation to the size of the machine – configuration of the device for stand-alone or in-line operation.